Home / Publications / E-library page

You are currently logged in as an

Institutional Subscriber.

If you would like to logout,

please click on the button below.

Home / Publications / E-library page

Only AES members and Institutional Journal Subscribers can download

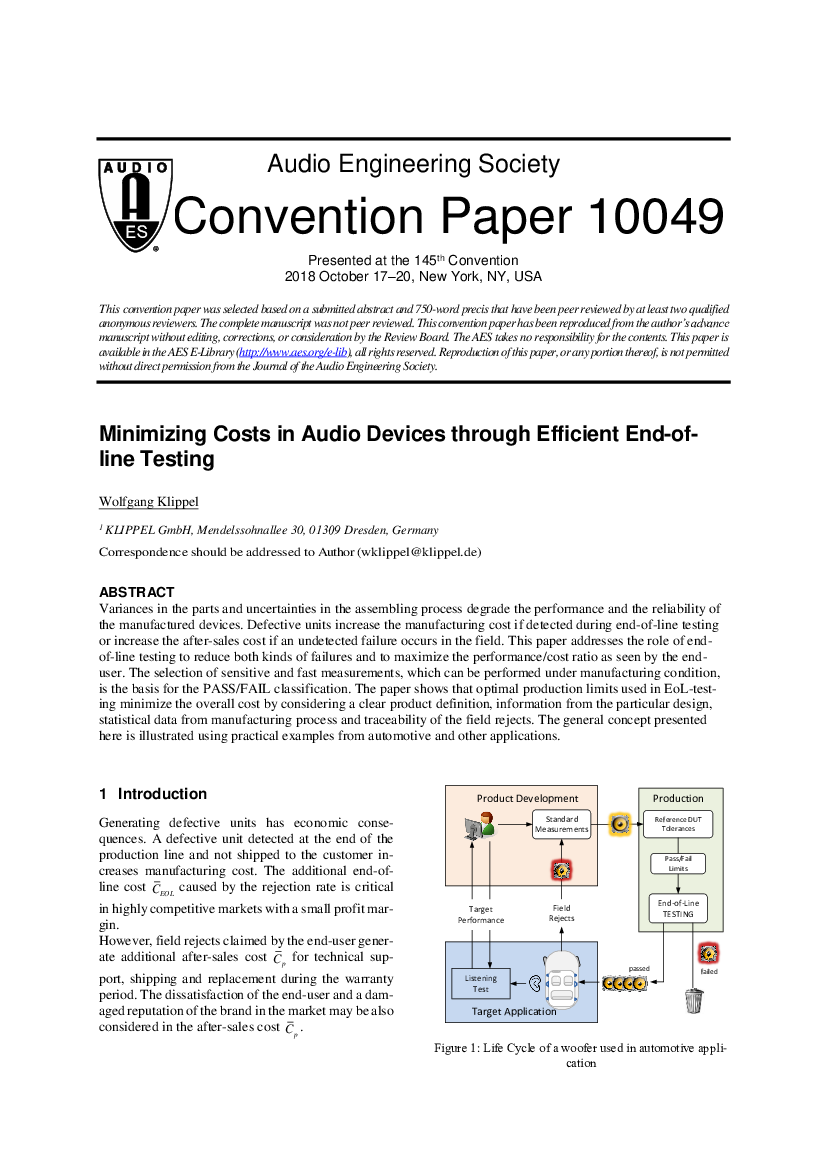

Variances in the parts and uncertainties in the assembling process degrade the performance and the reliability of the manufactured devices. Defective units increase the manufacturing cost if detected during end-of-line testing or increase the after-sales cost if an undetected failure occurs in the field. This paper addresses the role of end-of-line testing to reduce both kinds of failures and to maximize the performance/cost ratio as seen by the end-user. The selection of sensitive and fast measurements, which can be performed under manufacturing conditions, is the basis for the PASS/FAIL classification. The paper shows that optimal production limits used in EoL-testing minimize the overall cost by considering a clear product definition, information from the particular design, statistical data from manufacturing process and traceability of the field rejects. The general concept presented here is illustrated using practical examples from automotive and other applications.

Author (s): Klippel, Wolfgang

Affiliation:

Klippel GmbH, Dresden, Germany

(See document for exact affiliation information.)

AES Convention: 145

Paper Number:10049

Publication Date:

2018-10-06

Import into BibTeX

Session subject:

Transducers—Part 1

Permalink: https://aes2.org/publications/elibrary-page/?id=19775

(793KB)

Click to purchase paper as a non-member or login as an AES member. If your company or school subscribes to the E-Library then switch to the institutional version. If you are not an AES member Join the AES. If you need to check your member status, login to the Member Portal.

Klippel, Wolfgang; 2018; Minimizing Costs in Audio Devices through Efficient End-of-Line Testing [PDF]; Klippel GmbH, Dresden, Germany; Paper 10049; Available from: https://aes2.org/publications/elibrary-page/?id=19775

Klippel, Wolfgang; Minimizing Costs in Audio Devices through Efficient End-of-Line Testing [PDF]; Klippel GmbH, Dresden, Germany; Paper 10049; 2018 Available: https://aes2.org/publications/elibrary-page/?id=19775